There are three basic types of changes in thermochromic pigment: Decoloration series(Color to Colorless), Color-developing series(Colorless to color), and discolored(Color to Color).

Product name: Colorless to color reversible thermochromic pigment

Discoloration form: Colorless at low temperature, colored at high temperature. The color can be changed repeatedly.

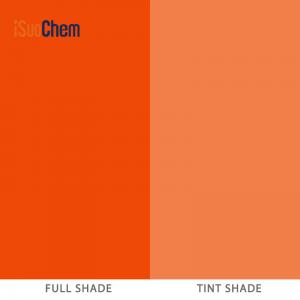

Basic thermochromic colors: Rose red, Peach red, Green, Emerald-green, Blue, Türkiye blue (Turkey blue), Sky blue, Orange, Violet, Black.

Customized color: Pantone color card number or actual color matching can be provided.

Commonly used temperatures: 35℃, 40℃, 60℃, 65℃.

Customized temperature: It can be customized according to customer needs.

The above temperatures are reversible temperatures, for example: 35 degrees blue, the temperature is lower than 35 degrees, it becomes colorless. When the temperature is higher than 35 degrees, it turns vermillion.

Thermochromic Paint

It is good for surface paints of various plastic products.

Such as ABS, PE, PP, PS, PVC, EVA, TPU, PC and other plastic materials, etc.

Thermochromic Ink

This versatile pigment is suitable for a wide range of printing inks, including coated screen, gravure, and letterpress prints. Moreover, it can be effectively applied to various materials such as textiles, paper, synthetic film, glass, ceramics, and wood.

Thermochromic Plastic

The common grade masterbatch, characterized by its high color concentration, can be blended with several materials including PE, PP, PS, PVC, EVA, PET, and Nylon for use in injection molding or extrusion processes.

Thermochromic pigment finds versatile applications in various industries, including yarn, fabric, leather, ceramics, and decorative items, among others.

Other Applications

Tips: Thermochromic Plastic (Plastic Grade) - iSuoChem has specially developed a thermochromic pigment known as "Plastic Grade" for application in plastics. This pigment boasts several distinctive features, including thick wall properties, standard strength, excellent heat resistance, improved dispersion capabilities for even distribution, and minimal residual color during the decolorization process.

+86 13965049124

+86 13965049124

English

English  français

français русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 ไทย

ไทย Tiếng Việt

Tiếng Việt