categories

recent posts

Will the glow in the dark powder be affected by temperature?

Yes, glow in the dark powder is affected by temperature.

iSuoChem Marketing Department / Edited by Jason

Regular glow in the dark powder or paint series

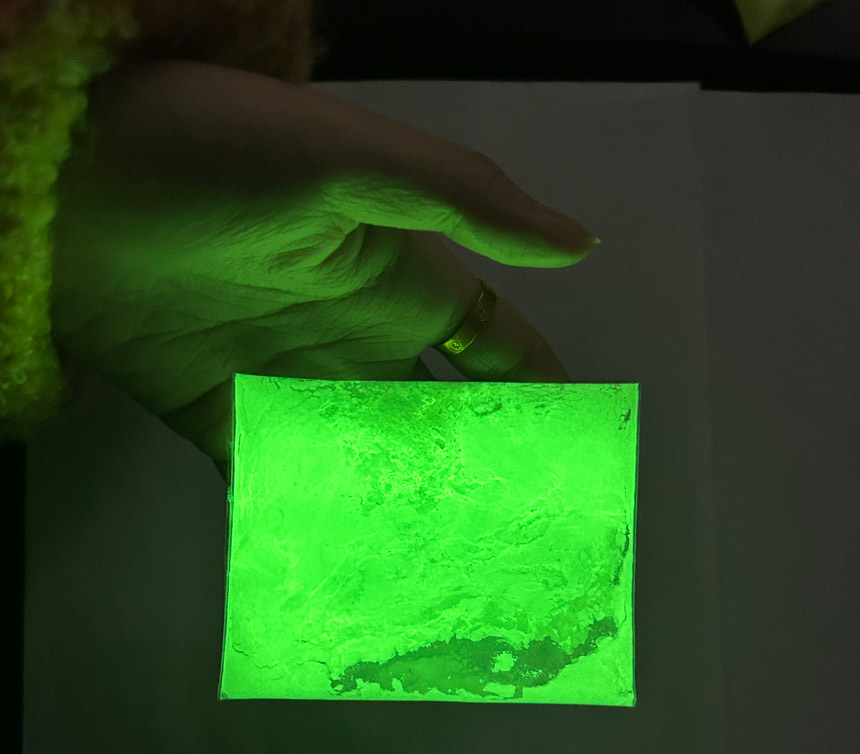

Glow in the dark powder is a special mineral powder that has the unique ability to absorb energy when exposed to light and then slowly release this energy in the dark to emit fluorescence. However, how glow in the dark powder performs at high temperatures depends largely on its composition and the method of making it.

Regular grade glow in the dark powder has a high temperature resistance range between 50°C and 80°C.

Heat-Resistant Glow in the Dark powder or paint

We have some heat resistant glow in the dark powder that can withstand temperatures in the range of 200-300℃. This type of glow in dark powder is already suitable enough for use in most products. Generally speaking, these glow pigments may start to lose their luster when the temperature exceeds 280 degrees Celsius, because the heat destroys the tiny structure inside the powder, which means that it cannot effectively absorb and release light energy.

If the glow powder is in a high temperature environment for a long time, it may change color, fade or even harden, which will affect its luminous effect. In some cases, it will even completely lose its luminous performance. Therefore, when using glow in the dark powder in a product, it is best to avoid long-term exposure to high temperatures.

Ceramic grade high temperature resistant glow in the dark powder or paint series

Given the sensitivity of glow in the dark powder to high temperatures, if you need to use it in a high temperature environment, you can choose luminous materials designed for high temperature environments (such as iSuoChem HCG and HCB ceramic grade glow in the dark powder series). These materials are made with special formulas and processes to keep their luminous properties stable at higher temperatures.

This ceramic grade glow in the dark powder can withstand temperatures up to about 800°C (Processing instantaneous temperature). Luminous ceramics are first made into glazes, which are then applied to the surface of ceramic blanks and fired to make surface ceramic products.

This kind of glowing glazes are mainly composed of three parts: glow in the dark powder, base glaze and additives.

Luminous glaze can be divided into three types according to the firing temperature: high temperature glaze, medium temperature glaze and low temperature glaze.

1. The firing temperature of high temperature luminous glaze is between 1050°C and 1200°C.

2. The firing temperature of medium temperature luminous glaze is between 980 and 1050 degrees Celsius.

Some customers feedback they can find glow in the dark powder which can resist 1000~1300°C. But according to our market experience and knowledge through the whole China market. It’s hard to resist 1000°C high temperature for glow in the dark powder in current technology conditions.

3. The firing temperature of low temperature luminous glaze is between 550 and 980 degrees Celsius.

If you want to add glow powder to ceramic production, we recommend that you use low temperature glaze. You can choose our Ceramic grade glow in the dark powder whose Max processing temperature is 800°C.

Injection molding grade heat resistant glow in the dark powder or paint series

In industrial production processes such as injection molding, temperature control is also a problem when using glow in the dark powder. In order to maintain the fluorescent effect of glow in dark powder, you must ensure accurate control of injection, maintenance and mold temperature. Otherwise, overheating may damage the powder. In addition, if the injection molding process parameters are adjusted (such as shortening the injection time and lowering the melt temperature), it can also help the glow in the dark powder cope with high temperatures.

In addition to temperature control, the surface of the product can also be treated (for example, by grinding, polishing or applying a transparent protective layer on it) to reduce the degree of erosion of the glow in dark powder by the external environment and protect its luminous properties. In addition, if the product is designed to protect the glow in the dark powder from damage such as high temperature or ultraviolet rays, its service life can be extended.

the professional team to service !