Introduction of applications: Pearl luster Printing Ink

With the development of printing technology, the application of pearl luster printing ink is becoming popular and popular. You can see it on the packages of cosmetics, cigarette case, wine, gift packing, business cards, greeting cards and so on. Pearl luster printing ink adopts Pearlescent Pigment to get special pearl luster which is different from metal pigment and helps to save cost which is welcomed by many customers. So the demand of pearl luster printing ink is getting bigger and bigger.

Composition of ink

Pearl luster printing ink is composed of pearl pigments, carriers and additives, and the pigments can be either powder or paste. The carrier is composed of resin and solvent in paste or fluid form, which is convenient for printing operation.

How to get best pearly effect

1, Choose the appropriate particle size and avoid grindin

Pearlescent pigment has excellent dispersibility. Generally, low viscosity ink can be mixed with light grinding. When we mix high viscosity inks, we don't have to grind vigorously. Since the particles of pearlescent pigments are flakes, selecting the pearlescent pigments with appropriate particle size plays a key role in the transfer of the ink and obtains the best pearlescent effect.

2, Distribute the pigment flakes of the ink as evenly as possible on the print substrates

When the pigment flakes are parallel to the printing substrates, the ideal pearly effect can be obtained. If the pigment is not wet thoroughly by solvent, the pearlescent pigment will be dispersed into the ink asymmetrically and the pearlescent effect will be reduced. Choosing the right printing method can avoid adverse effects on the printing effect, and glossy & smooth surface of printing substrates can help to achieve better printing results. In addition, the relationship between the silkscreen, particle size of the pigment, viscosity of the ink, printing speed, drying conditions, pigment flocculation or dispersion, and the distribution of the ink are all very important. The specificity required for pearlescent pigments depends on the mixing conditions in the ink.

Printing methods

The general printing methods are letterpress printing, flexographic printing, intaglio (gravure) printing, surface printing, silkscreen printing and offset printing. In different printing methods, there are differences in the use of pearlescent pigments. In general, the main factors affecting the pearly effect are the printing method, the characteristics of the ink, the transfer of the ink, the color and the type of the printing substrate, etc.

Printing method and recommendation of pearl pigment

A. Letterpress Printing

Letterpress printing may be the earliest printing method used by mankind. The letterpress ink is a paste, the viscosity ratio is between 50-300 poise, and the average particle size of the pearlescent pigment is about 10-20um, because exceeding this size will bring problems to the printing process. The following pearlescent pigments are our recommendation for letterpress printing: AS120, AS123, AS111, AS110, etc.

B. Flexographic Printing

Flexographic printing is similar to letterpress printing. It has a viscosity ratio between 50-300 poise. It requires that the particle size of pearlescent pigments is smaller, below 10um-20um. Pearlescent pigments suitable for letterpress printing are also suitable for flexographic printing.

C. Intaglio Printing

Intaglio printing is also called gravure printing. The viscosity ratio is very low, for about 20 to 60 poise. It has no limitation to solvent type. Except for blink type and highlight type, all the iSuoChem pearl pigments are suitable for intaglio printing.

The depth of printing screen roller largely determines the particle size of pearl pigment. However, the following pigments are suitable for texture depth of 35-55um and 70-120um.

The recommended pearlescent pigments for intaglio printing are as follows:

Net line (size)

|

Smallest depth (um)

|

Recommended type

|

200

|

25

|

110,111 and so on

|

|

175

|

35

|

120,118,121,122

|

|

120

|

65

|

100, metal and interference series

|

|

75

|

120

|

153 and so on

|

D. Surface printing

Similar to intaglio printing, Surface Printing also uses ink with low viscosity ratio. Almost all the pearl pigments are suitable for it except for blink and highlight types.

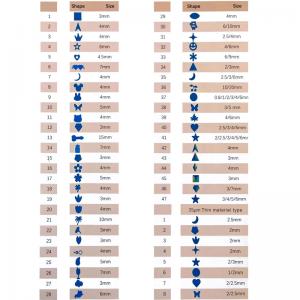

E. Silkscreen printing

All the pearl pigments are suitable for silkscreen printing. We should pay attention that pearl pigment with big particle size requires coarser silkscreen. The mesh of silkscreen determines the average particle size of pearl pigment. For example, 200 mesh of silkscreen (74um) is suitable for the above pigments stated. But blink and highlight type of ink requires bigger silkscreen mesh, such as 80mesh or 177um.

Tips: Dispersing of pearl pigment

When formulating pearl luster printing ink, pearlescent pigment should be added in the last phase. It also means we can add it when the other raw materials are well mixed. This avoids damage from excessive shearing.

During production, first fully wet the pearlescent pigment with a small amount of solvent, then add a small amount of carrier ink and stir evenly. Finally, the dispersed ink is put into the remaining transparent ink for further mixing and dispersion. Mix at low shear and high speed. It takes about 15 minutes for uniform dispersion. To avoid damage to the pigment, high shear mixers such as ball mills, stone mills and three-rollers are not allowed.

More questions:

The usual problem and methods for pearl ink?

+86 13965049124

+86 13965049124

English

English  français

français русский

русский italiano

italiano español

español português

português العربية

العربية 한국의

한국의 ไทย

ไทย Tiếng Việt

Tiếng Việt